THE KALINGA PROJECT

Introducing Desktop Manufacturing & Recycling to the Philippines

The goal of The Kalinga Project is to spread awareness about the cultures of The Philippines, discover how to improve quality of life by developing Filipino-American relations with the tribes in the Kalinga area and the greater surrounding Cordilleras. We intend on doing this by teaming up with the tribes of the Cordilleras, developing recycling facilities and infrastructure that would allow for the development of 3d printing farm and a manufacturing industry in Cordilleras.

OUR SERVICES

OUR PRODUCTS

TATTOO TOURS

3D PRINTING IN BUSCALAN

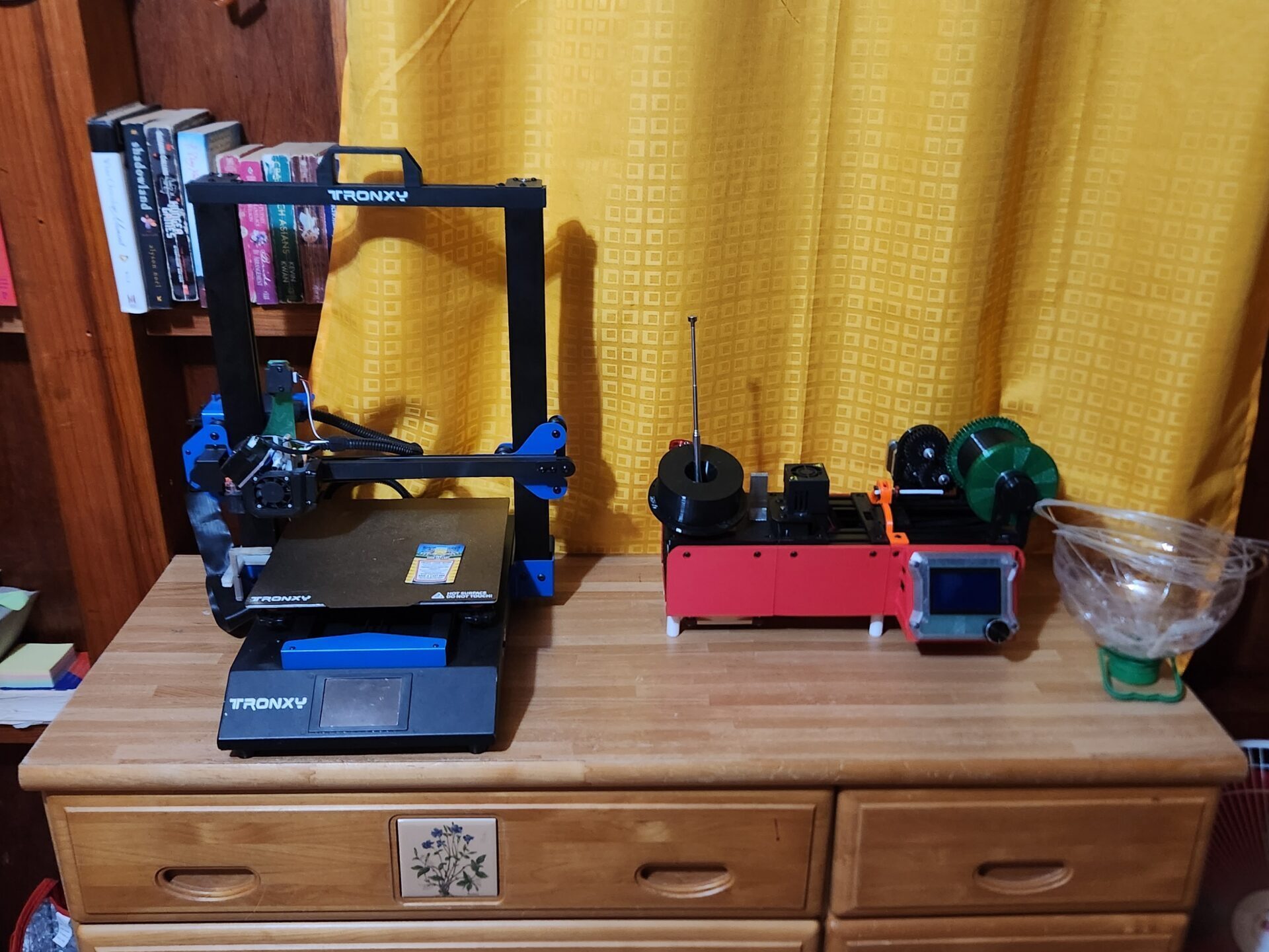

In the video above we are printing the second part of a component for the 3d printer. The vision is to have 3D Printer using the material you recycled right in your home using perhaps a ReCreator3d pultrusion style plastic recycler.

P.E.T. RECYCLING IN BUSCALAN

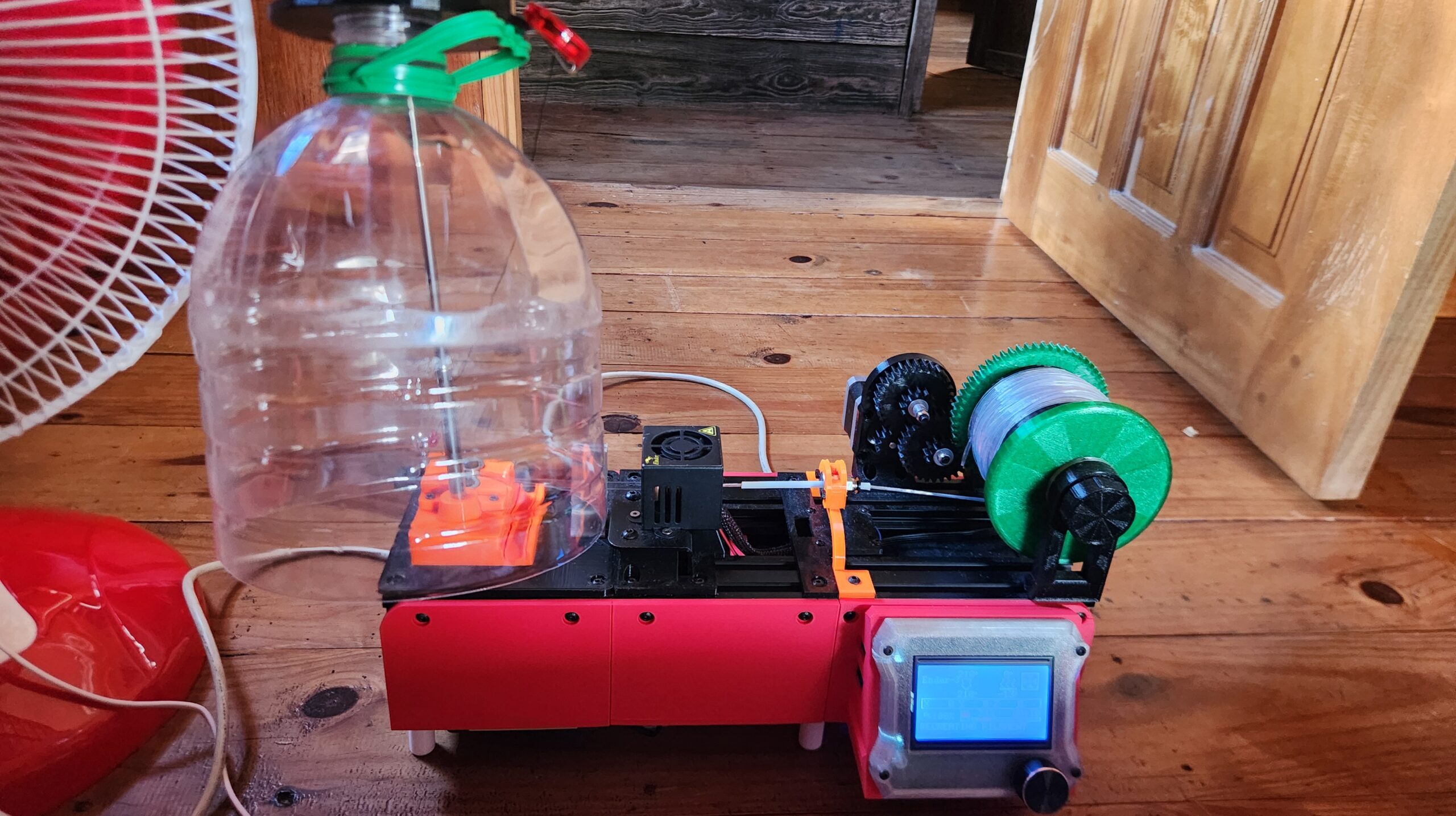

Unlike conventional 3D filament manufacturing which extrudes or pushes material through a die, the Recreator3D’s “pultrusion” method pulls melted and processed plastic, often from recycled sources, through a heated hole to create a consistent diameter of filament, similar to the process of making fiber-reinforced plastics.

The Plastic Problem

Massive Plastic Waste Generation

The Philippines produces about 2.7 million tons of plastic waste annually, largely from single-use sachets and packaging, driven by the widespread “sachet economy” that caters to low-income consumers with small, affordable product portions.

- World Bank (2023). Market Study for Philippines: Plastics Circularity Opportunities and Barriers. “A staggering 2.7 million tons of plastic waste are generated in the Philippines each year, and an estimated 20 percent ends up in the ocean.”

- Heinrich Böll Foundation (2025). PHILIPPINES: Reducing Plastic Waste Isn’t in the Bag — Yet. “The Philippines generates some 2.7 million tonnes of plastic waste annually and 20% of that goes to the ocean, according to the World Bank. ‘Sachet economy’ and ‘high dependence’ on single-use plastics continue to worsen the alarming levels of marine plastic pollution.”

A Potential Solution

Recycle Plastic Waste for Additive Manufacturing

In the Philippines, where innovative recycling programs under the Ecological Solid Waste Management Act and the newly launched National Plan of Action on Plastic Pollution are making strides to manage over 2.7 million tons of annual plastic waste, supplementing these efforts with grassroots technologies promises a transformative leap toward a circular economy. One of many empowering tools in this arsenal is the Recreator3D PET recycler, a low-cost, DIY pultrusion machine that ingeniously converts discarded PET bottles—ubiquitous symbols of everyday waste—into high-quality 3D printing filament, rivaling commercial PETG in strength and versatility while slashing production costs by repurposing salvaged printer parts. This not only diverts plastic from overflowing landfills and polluted waterways but also fosters community-driven innovation, enabling local makers in resource-scarce areas to craft durable tools, cultural artifacts, and sustainable products that honor indigenous ingenuity while curbing carbon emissions and energy use by up to 80% compared to virgin materials. By weaving such accessible tech into the fabric of national initiatives, we unlock a vibrant future where waste becomes wonder, empowering Filipino communities to print their way to environmental resilience and economic vitality.

Success In Buscalan

Introducing 3d Printing & ReCreator to Buscalan, Kalinga

In April of 2025 we successfully recycled an 8 liter water bottle using the ReCreator3d. We recovered enough plastic for approximately 4 small prints. Approximately one hour was required to recycle the 8Lwater bottle.

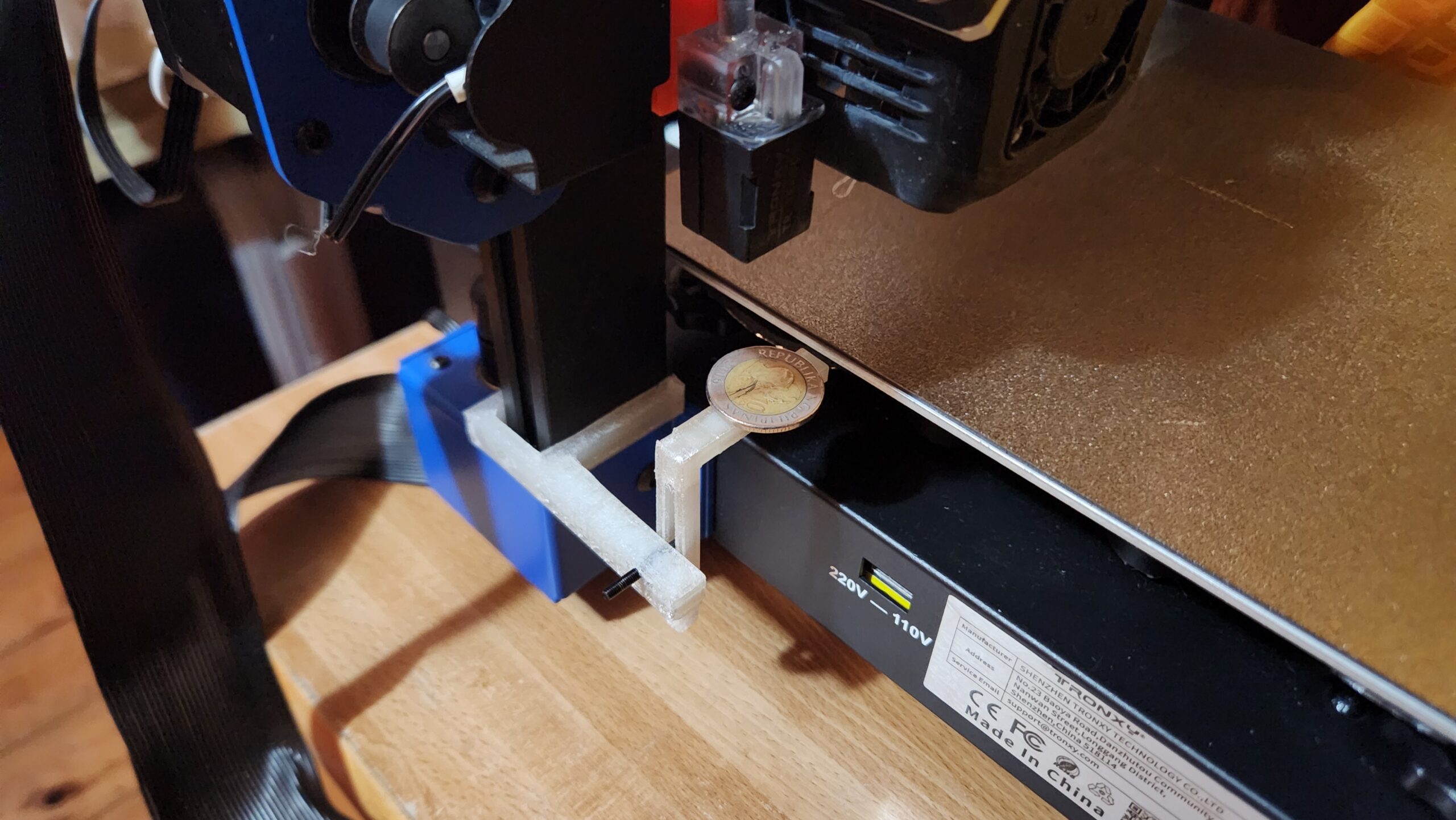

Our first print for the stand of the sensor succeeded with no issues other than high humidity as we did not have a filament dryer. The following to prints failed due to power loss caused by the typhoons. The fourth and final print was successful allowing us to trial fit the replacement sensor bracket.

What Now?

It’s Time to Build the Industry

As we approach 2026 we are buttoning up our plan to go live with The Kalinga Project in Washington state or the United States. We are just now wrapping up the web site, the products we plan to sell are designed and our presently being prototyped in our 3d printer. The long term goal for this US based business is to become a Charitable Organization also known as a B-Corp so that we may proactively spread the knowledge and education about these tools. Our goal is to develop a successful method to deploy this technology not only in the Philippines but where ever it could be useful.